Imagine a world where machines handle the heavy lifting, allowing humans to focus on creativity and innovation. Industrial robots are revolutionizing the manufacturing landscape, streamlining processes and boosting productivity like never before. From automotive assembly lines to electronics production, these advanced machines are becoming indispensable.

In this article, you’ll discover a variety of industrial robots examples that showcase their versatility and efficiency across different sectors. Whether you’re curious about collaborative robots working alongside humans or powerful robotic arms performing intricate tasks, there’s much to explore. How do these robots enhance operations and what makes them essential in today’s industry? Dive in as we unveil the fascinating world of industrial robotics and highlight some standout examples that are shaping the future of work.

Overview of Industrial Robots

Industrial robots play a critical role in modern manufacturing. They automate tasks, enhance precision, and improve efficiency. Here are some notable examples:

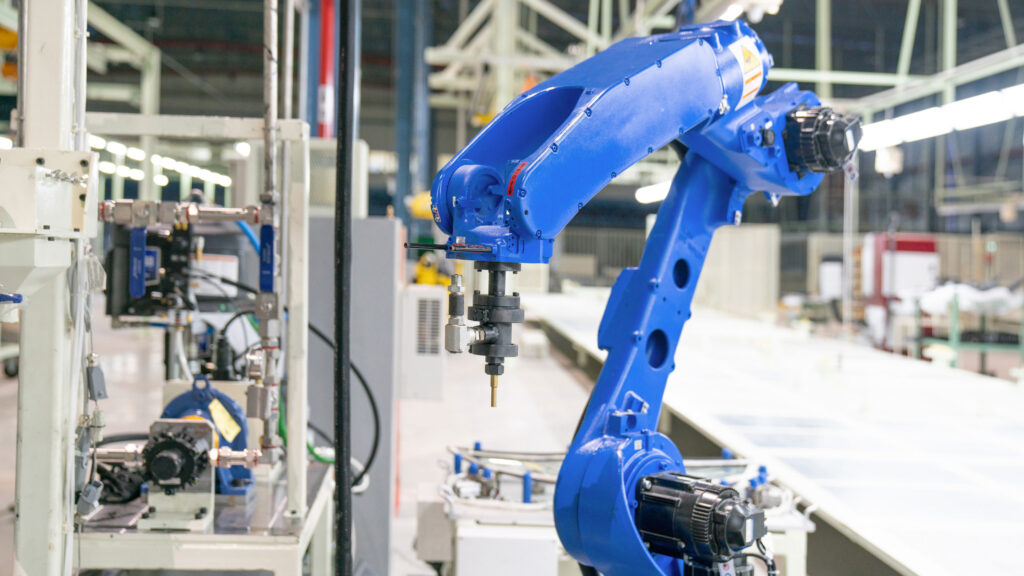

- Articulated Robots: These robots consist of multiple joints that mimic a human arm’s movement. They’re commonly used in assembly lines for welding and painting.

- SCARA Robots: Selective Compliance Assembly Robot Arm (SCARA) specializes in high-speed applications like pick-and-place tasks. Their design allows them to work effectively in confined spaces.

- Delta Robots: Built for speed and agility, these parallel robots excel in packaging and sorting items rapidly on production lines.

- Collaborative Robots (Cobots): Designed to work alongside humans, cobots assist with repetitive tasks while ensuring safety through advanced sensors.

Each robot type serves distinct functions across various industries, boosting productivity significantly. Would you consider integrating one of these robots into your operations?

Types of Industrial Robots

Industrial robots come in various types, each designed for specific tasks in manufacturing. Understanding these types can help you identify which robot suits your operational needs best.

Articulated Robots

Articulated robots feature rotary joints that allow them to mimic human arm movements. These robots excel in tasks like welding, painting, and assembly. For example, the ABB IRB 6700 is known for its versatility and strength, making it ideal for heavy-duty applications. Their flexibility makes them suitable for complex tasks requiring precision and dexterity.

SCARA Robots

SCARA robots are perfect for high-speed pick-and-place operations due to their unique design. They move with a horizontal arm configuration that allows quick lateral movements. The Yaskawa Motoman SCARA series stands out in industrial settings by handling tasks like packaging and material transfer efficiently. This speed helps improve productivity while maintaining accuracy in repetitive processes.

Cartesian Robots

Cartesian robots operate on three linear axes using a rectangular coordinate system. They’re often used for precise positioning and handling heavy loads. An example is the FANUC M-1iA, which offers excellent repeatability and speed in assembly lines or material handling applications. Their straightforward design simplifies programming, making them user-friendly even for those new to robotics.

By exploring these different types of industrial robots, you can determine how each might enhance your manufacturing processes effectively.

Applications of Industrial Robots

Industrial robots play a vital role in various sectors, enhancing efficiency and precision. They automate tasks that are repetitive or require high accuracy, leading to improved productivity.

Automotive Industry

In the automotive industry, industrial robots handle tasks like welding, painting, and assembly. For example, the KUKA KR series is renowned for its speed and flexibility in welding applications. These robots ensure consistent quality while reducing cycle times. Furthermore, they can adapt to different vehicle models with ease. This adaptability significantly impacts production efficiency.

Electronics Manufacturing

Electronics manufacturing relies heavily on robotics for assembly and testing processes. The Universal Robots UR series exemplifies collaborative robots designed for tasks such as circuit board assembly. They work alongside human operators without safety cages, increasing operational flexibility. Additionally, these robots excel at handling delicate components with precision.

Food and Beverage Sector

In the food and beverage sector, industrial robots streamline packaging and sorting tasks. The FANUC M-20iA robot efficiently manages pick-and-place operations in packaging lines. This model handles various products quickly while maintaining hygiene standards critical in food processing environments. Moreover, its ability to operate continuously reduces labor costs significantly.

By integrating industrial robots into these sectors, companies enhance their production capabilities while ensuring high-quality output across all operations.

Notable Industrial Robots Examples

Industrial robots play a vital role in modern manufacturing, showcasing various capabilities across numerous sectors. Here are some notable examples that illustrate their effectiveness.

KUKA Robotics

KUKA offers a range of industrial robots known for their flexibility and speed. The KUKA KR series excels in tasks like welding and assembly. Key features include:

- High payload capacity: Handles heavy components efficiently.

- Versatile applications: Adaptable to different industries, including automotive.

- Advanced programming options: Simplifies integration into existing workflows.

With these attributes, KUKA robots enhance productivity while ensuring consistent results.

FANUC Robots

FANUC is renowned for its reliable and efficient robotic solutions. Their models cater to diverse applications, such as the FANUC M-20iA. Highlights include:

- Superior precision: Ideal for intricate assembly tasks.

- Robust design: Built to withstand demanding environments.

- User-friendly interface: Makes programming straightforward for operators.

These qualities enable FANUC robots to boost operational efficiency across various settings.

ABB Industrial Robots

ABB’s industrial robots are recognized for their strength and versatility, particularly the ABB IRB series. Important characteristics include:

- Articulated movements: Mimics human-like dexterity for complex tasks.

- Wide application range: Suitable for welding, painting, and material handling.

- Energy efficiency: Reduces operating costs while maintaining performance.

With these features, ABB robots contribute significantly to enhancing manufacturing processes globally.

Future Trends in Industrial Robotics

Innovations in industrial robotics continue shaping the manufacturing landscape. Increased collaboration between humans and robots is a key trend. Collaborative robots, or cobots, are designed to work alongside human operators safely. They enhance productivity without replacing the workforce.

Advancements in artificial intelligence (AI) drive efficiency. AI-powered robots can learn from their environment and improve their performance over time. This adaptability allows for more complex tasks such as quality inspection and predictive maintenance.

Integration of Internet of Things (IoT) technology enhances connectivity. IoT-enabled robots share data with other machines and systems in real-time. This connectivity streamlines operations and provides valuable insights for decision-making processes.

Here are some notable future trends:

- Increased automation: More companies adopt robotic solutions to automate repetitive tasks.

- Enhanced sensory capabilities: Robots equipped with advanced sensors improve precision in various applications.

- Sustainability focus: Eco-friendly robotics designs emphasize energy efficiency and reduced waste.

These developments highlight that industrial robots will become even more essential across sectors like automotive, electronics, and food processing. As you explore these trends, consider how integrating these technologies could benefit your operations.