When you think about safety hazards, do explosives and flammable aerosols come to mind? These substances play a crucial role in various industries but can pose significant risks if not handled properly. Explosives, flammable aerosols, and oxidizing gases are examples of materials that require careful management to ensure safety. Understanding these elements is essential for anyone involved in manufacturing, construction, or even everyday activities like using household products.

In this article, you’ll explore the different types of explosives and flammable aerosols, along with their uses and potential dangers. By recognizing the characteristics of these materials, you can better appreciate their impact on both industry and personal safety. Whether you’re a professional or just curious about what makes these substances tick, you’ll find valuable insights that could help prevent accidents and enhance your knowledge. Ready to dive deeper into this fascinating topic?

Understanding Explosives

Explosives are materials that undergo rapid chemical reactions, releasing energy in the form of gas and heat. Recognizing their types and applications helps ensure safety in handling these potentially dangerous substances.

Types of Explosives

- Blasting Agents: These require a strong detonator for initiation. Examples include ANFO (Ammonium Nitrate Fuel Oil) used in mining.

- Low Explosives: These burn at a slower rate and produce gas over time. Common examples are black powder and smokeless powder, often found in firearms.

- High Explosives: These detonate rapidly, creating shock waves. TNT (Trinitrotoluene) is one well-known example used in military applications.

Applications of Explosives

Explosives serve various purposes across multiple industries:

- Construction: Used for demolition or excavation, explosives efficiently break apart rock or structures.

- Mining: In this sector, they help extract minerals from the earth by fragmenting rock layers.

- Military: Weapons systems utilize explosives for ordinance delivery, including bombs and missiles.

- Special Effects: Film productions often employ controlled explosions to create realistic action sequences.

By understanding these aspects of explosives, you can appreciate their significance while acknowledging the precautions necessary for safe usage.

Flammable Aerosols

Flammable aerosols are widely used materials that can pose significant safety risks if not handled properly. These substances, found in various products, require a clear understanding of their properties and associated safety considerations.

Properties of Flammable Aerosols

Flammable aerosols contain propellants and solvents that can ignite easily. Some key properties include:

- Volatility: Many flammable aerosols evaporate quickly, increasing the risk of fire.

- Flash Point: This is the lowest temperature at which vapors ignite. Products like aerosol sprays often have flash points below room temperature.

- Density: The density affects how these aerosols disperse in the air. Heavier-than-air aerosols tend to settle in low areas.

Understanding these properties helps you recognize potential hazards when using or storing flammable aerosols.

Safety Considerations

Safety is crucial when working with flammable aerosols. Here are essential precautions to consider:

- Storage: Store in a cool, well-ventilated area away from heat sources and direct sunlight.

- Usage: Use only as directed on labels and avoid inhaling vapors.

- Disposal: Dispose of empty cans according to local regulations; never puncture or incinerate them.

By following these guidelines, you reduce the risk of accidents while ensuring safe usage of flammable aerosol products.

Oxidizing Gases

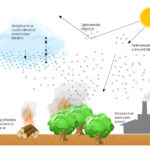

Oxidizing gases play a crucial role in combustion processes. They provide the necessary oxygen for fuels to ignite and burn efficiently. Understanding these gases helps you recognize their significance in various applications, from industrial manufacturing to laboratory experiments.

Role of Oxidizing Gases in Combustion

Oxidizing gases enhance combustion efficiency by increasing the amount of available oxygen. When mixed with flammable materials, they promote rapid chemical reactions that release energy. For instance, without oxidizing gases, many fuels simply won’t ignite or burn effectively. Do you see how essential they are?

Common Oxidizing Gases

Several common oxidizing gases exist, each with unique characteristics:

- Oxygen (O₂): Essential for most combustion processes; it supports burning.

- Nitrous Oxide (N₂O): Used in rocket propulsion and as an anesthetic; it increases combustion stability.

- Chlorine (Cl₂): Employed in water treatment and chemical synthesis; it’s highly reactive.

- Hydrogen Peroxide (H₂O₂): Utilized as a disinfectant and bleaching agent; it decomposes into water and oxygen.

These examples illustrate how different oxidizing gases contribute to various industries while highlighting their potential hazards if mishandled.

Risks and Regulations

Handling explosives, flammable aerosols, and oxidizing gases involves various risks that necessitate strict regulations. Understanding these regulations ensures a safer environment for everyone involved.

Safety Regulations

Safety regulations govern the handling of hazardous materials like explosives and flammable aerosols. These laws include:

- Occupational Safety and Health Administration (OSHA) standards that establish safety protocols in workplaces.

- Environmental Protection Agency (EPA) guidelines that regulate disposal methods for harmful substances.

- Department of Transportation (DOT) requirements for transporting dangerous goods safely.

These organizations play a crucial role in minimizing hazards associated with these materials.

Prevention Measures

Implementing effective prevention measures can significantly reduce risks when working with hazardous materials. Consider the following strategies:

- Training employees on proper handling techniques to prevent accidents.

- Using appropriate storage containers designed for specific types of materials to avoid leaks or explosions.

- Conducting regular safety audits to identify potential hazards before they lead to incidents.

By prioritizing these measures, you foster a culture of safety in your workplace or home environment.